Home

Solutions for

track construction and vehicles

Contact

Maintenance and modernization

We solve challenges at the maintenance or modernisation of railway track systems and rail vehicles throughout Europe

rails

brush, test, glue, lift and more

sleepers

flatten, concrete, renew and more

sets

repair, manipulate, brush and more

Track construction

The maintenance and renewal of track systems poses many challenges for those who maintain the infrastructure.

We like to take our time and develop the right solutions or have them already made.

Here are some of the solutions we came forward with in the past years, based on customer problems.

Brushing machine

cleaning tracks automatically

Button

Adhesion table

sticks tracks with an isolation

ButtonRail crane

assists at loading rails

ButtonSafety pliers

for fixing rails during manipulation

Button

Test press

tests elasticity of rails

ButtonFlattening machine

semi automatic

Button

Prestressing machine

for prestressing iron in concrete sleepers

Button

Processing machine

for processing concrete sleepers

Button

Railroad tracks

Railway tracks require regular maintenance. Removing, transporting and cleaning old rails requires special technical solutions.

We have developed special machinery for problems in maintenance and modernization of rail infrastructure throughout Europe. New solutions are always developed on customer problems. Here is a small selection of previous solutions:

- FMU brushing machine takes over the cleaning of rails semi-automatically. The rail head and rail base are prepared for welding. This makes the maintenance of used railway tracks much more efficient.

- FMU adhesion table supports the gluing of insulating joints with millimeter precision for automated train monitoring. The insulation required for electrical separation is precisely placed in the adhesion press.

- FMU plating machine seperates wooden sleepers, drills precise holes, screws the panels, stacks and straps the finished, serviced wooden sleepers at a cycle time of 2 sleepers per minute.

- FMU test press can test vertical and tensile forces on used rails. In this way the quality of the maintenance of railway tracks can be guaranteed.

- FMU rail crane enables easy loading and unloading of the rail on transport wagons. The fmu safety pliers are also used, which make lifting and lowering rails weighing tons safer and preventing them from slipping.

- FMU prestressing machine accelerates the production of concrete sleepers by automatically prestressing the iron wires before entering concrete. This also guarantees a uniform quality of the sleepers.

- FMU processing machine supports the production of concrete sleepers together with the wire tensioning device. The long cast is then cut to the necessary threshold width.

Sets

The maintenance and renewal of railway vehicles also poses challenges for the workshop.

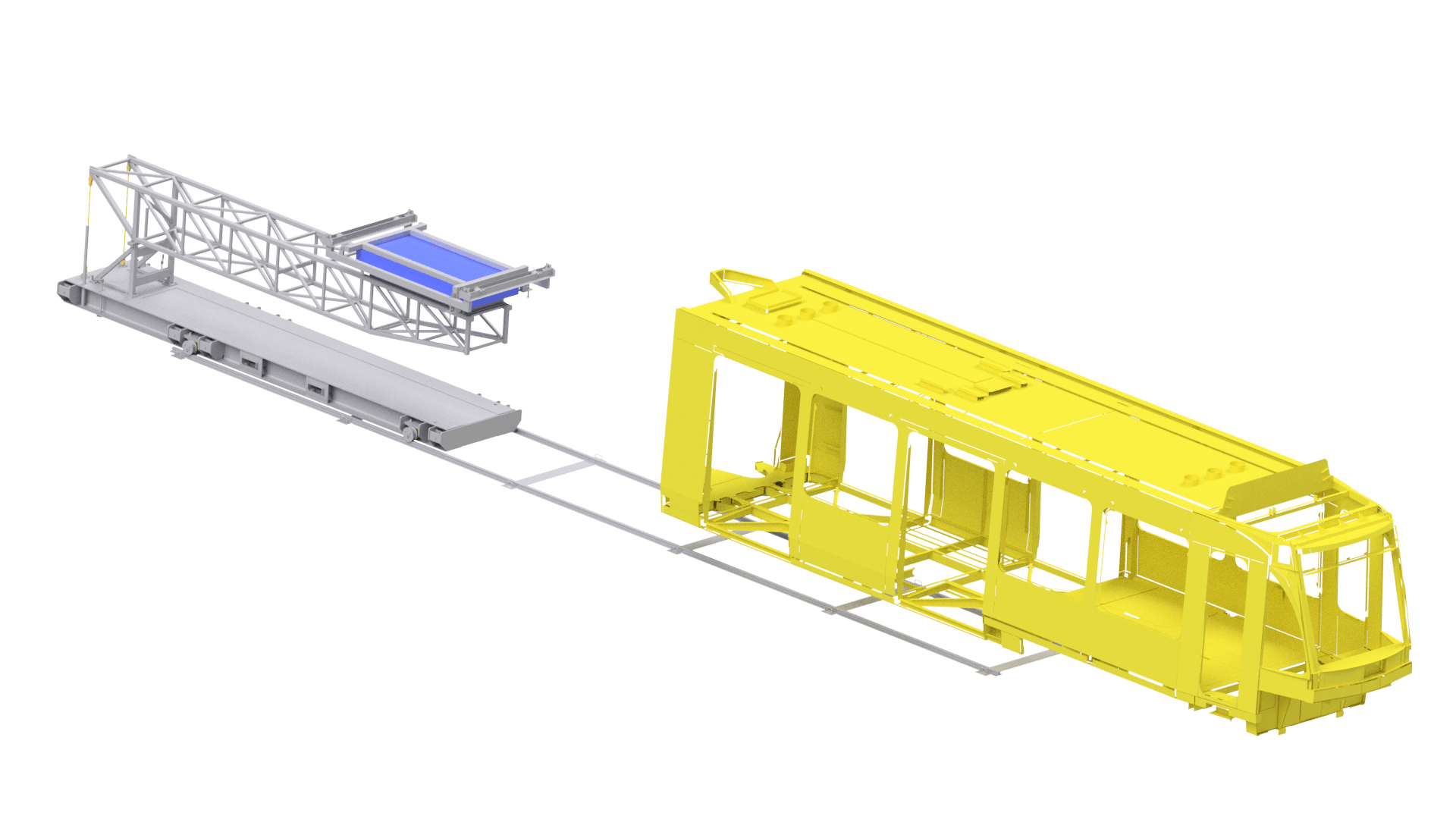

Transport line

manipulates semi-produced vehicles

Button

Remediation pit

mobile maintenance for long vehicles

Button

Manipulator

places heavy parts during production

Button

High-Bay warehouse for axles

optimizes your stock

Button

Rail vehicles

Vehicle sets are regularly serviced and sometimes completely renewed. Large, heavy parts that can hardly be moved manually are often to be replaced. We have developed special systems for this, which greatly simplify the manipulation of heavy components in the workshop.

- FMU transport line is a conveyor belt between the individual production steps at the assembly of Flexity 2 cabins.

- FMU manipulator for built-in roofs helps in the production of train sets by correctly positioning the built-in roofs for the assembly.

- FMU remediation pit is mobile. We come to your remise and you can work on subfloors of long range sets (up to 150 meters) with dry ice or sand blasting.

- FMU high-bay warehouse for axles can carry and store the multi-ton axles on several levels to save space. A container crane is used for manipulation.

Our references

Our partners

Contact us + 43 2772 530590

Thank you for contacting us.

We will contact you as soon as possible.

We will contact you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Please try again later.

FMU Förderanlagen Maschinenbau Umwelttechnik GmbH

Hauptstrasse 7, 3051 St. Christophen, Austria

|

43 2772530590

Copyright © All rights reserved.